what are the three basic areas of a machine that require safeguarding

Machine safeguards must meet these minimum general requirements. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands.

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Guards are barriers which prevent access to danger areas.

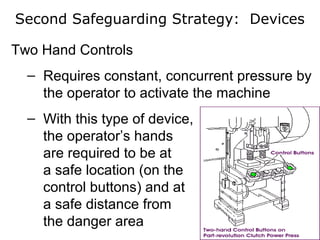

. That point where work is performed on the material such. Aside from guards another common safeguarding method is. The point of operation that point where work is performed on the material.

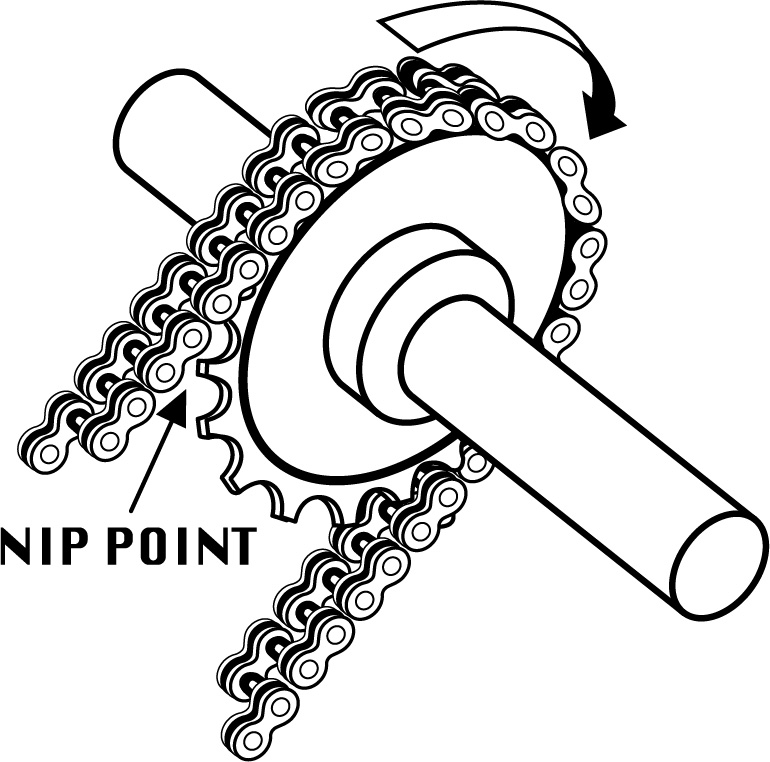

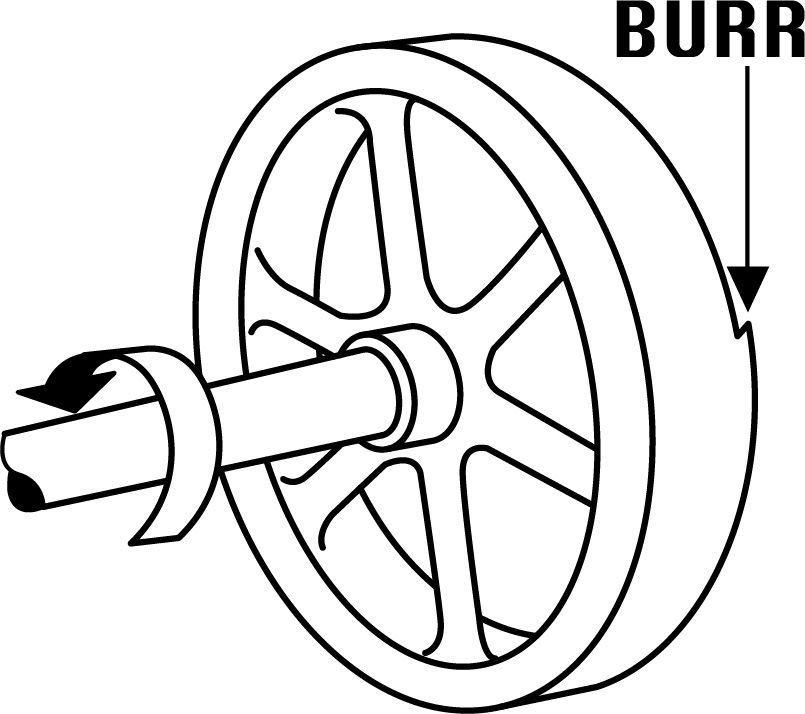

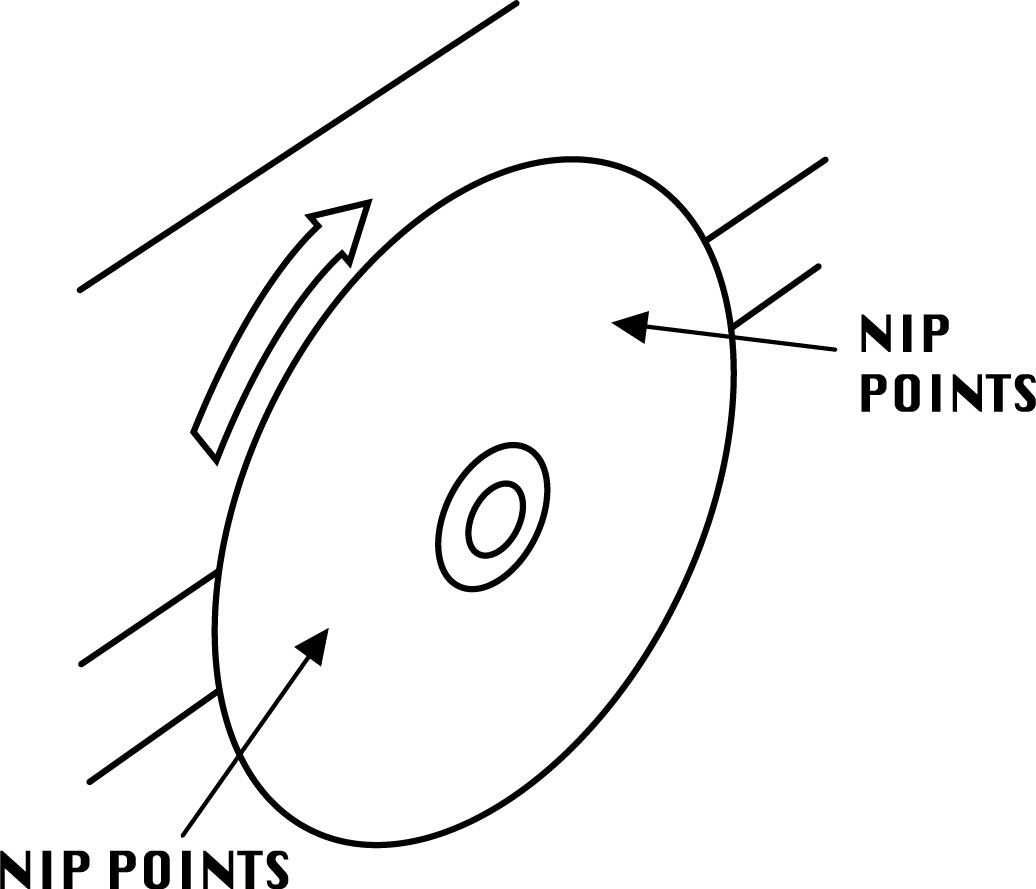

Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts that need safeguarding are located in the three basic areas described below. What are the three basic areas of a machine that require safeguarding.

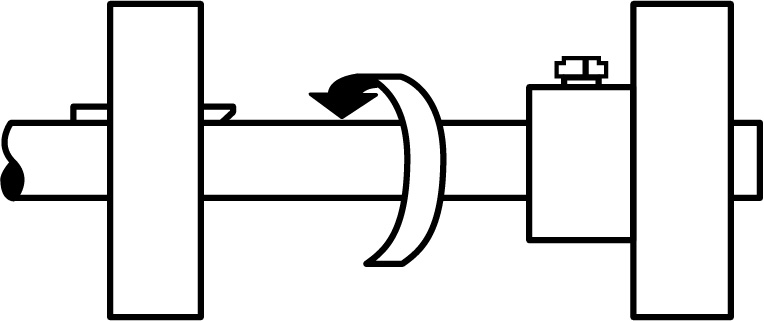

Dangerous moving parts in three basic areas require safeguarding. Despite all machines having the same basic components. The point of operation the power transmission device and the operating controls.

All machines consist of three fundamental. Machine safeguarding helps protect. The point of operation is the point where.

Mechanical hazards typically involve dangerous moving parts in the following three basic areas. The safeguard must prevent hands arms or any other part of a workers body from contacting. Recent fatalities involving confined spaces demand that these areas be given more attention to reduce risk of injury or loss of life.

OSHA Safety and Health Information Bulletin SHIB January 25 2013. Point of Operation Power Transmission Apparatus Other Moving Parts Question 2. Dangerous moving parts in three basic areas require safeguarding.

The point of operation. Methods of Machine Safeguarding. The point of operation.

Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding. Where Mechanical Hazards Occur.

Mechanical hazards typically involve dangerous moving parts in the following three basic areas. The point of operation. All machines consist of three fundamental areas.

That point where work is performed on the material such as cutting shaping boring or forming of. Moving machine parts create workplace hazards and potential machinery-related injuries making machine guards vitally important. That point where work is performed on the material such as cutting shaping boring or forming of.

The area on a machine where work is actually performed on the material being processed eg cutting.

Chapter 1 Basics Of Machine Safeguarding

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

Osha 10 Hour Machine Guarding Presentation 4

Osha Requirements Machine Guarding Grainger Knowhow

Machine Guarding Environmental Health Safety

Osha 10 Hour Machine Guarding Presentation 4

What Are The Types Of Machine Guards Quad Plus

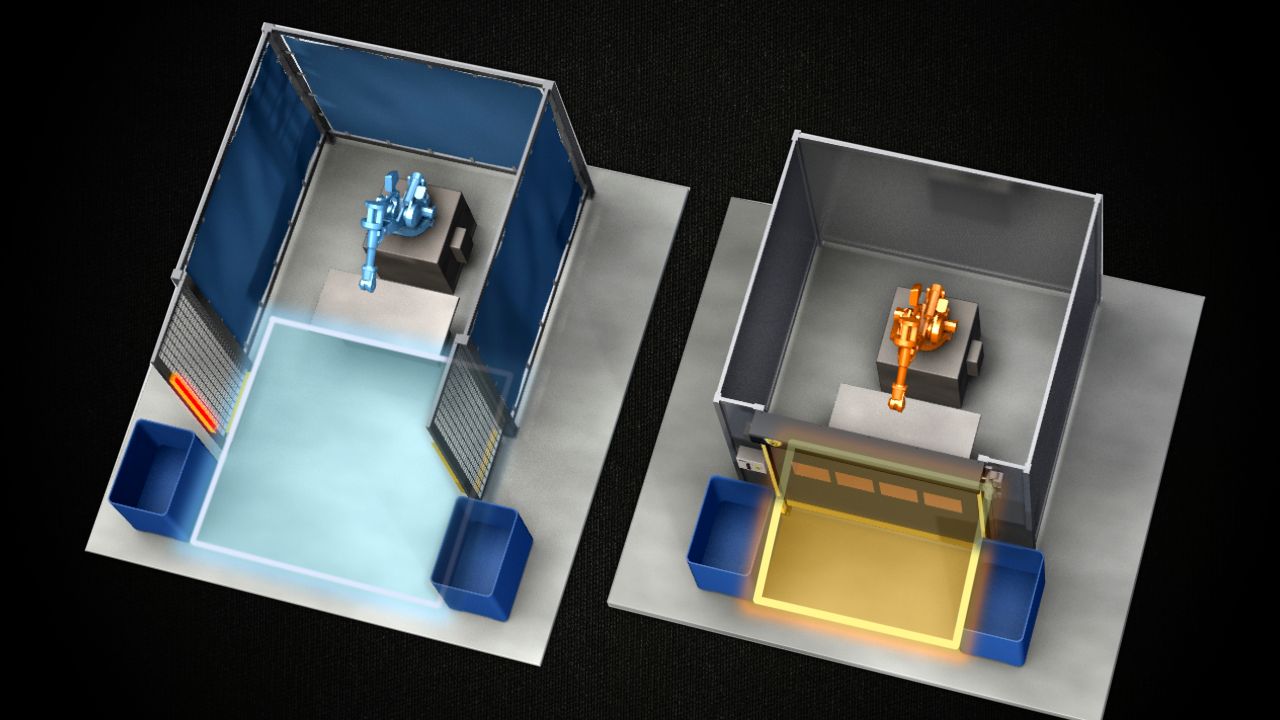

Machine Guards Safety Fencing Doors Curtains Screens Rite Hite

Managing Health And Safety Lecture 2 Plan 1 Occupational Safety And Health In Russian Federation 2 Labour Legislation 3 International Management Systems Ppt Download

Machine Safeguarding By Location And Distance

Osha Requirements Machine Guarding Grainger Knowhow

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Osha Standards Part 2 The Basics Of Machine Guarding

The Anatomy Of A Machine Safeguarding Project